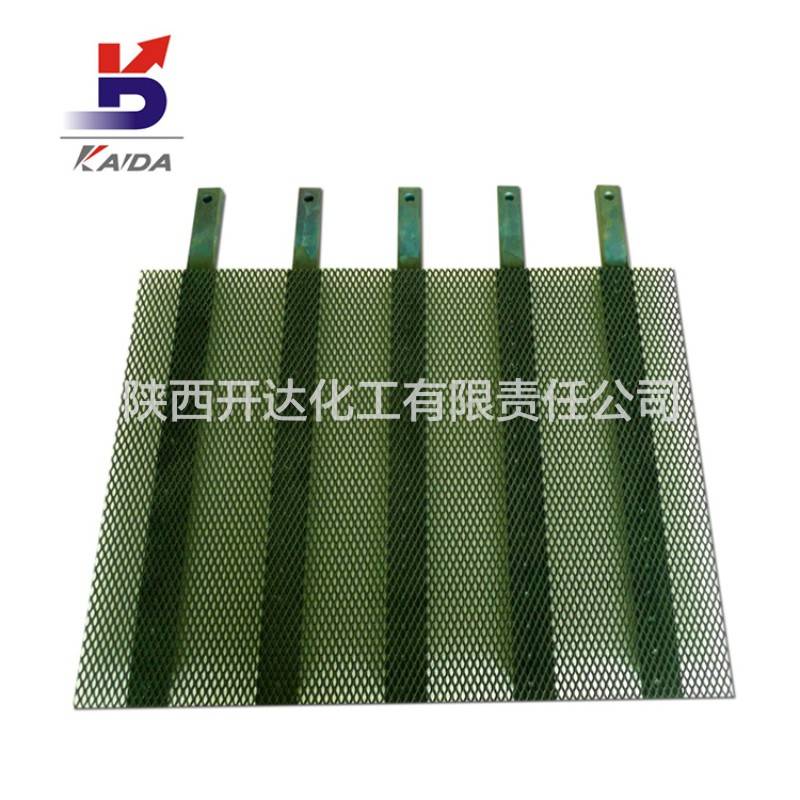

Iridium-tantalum dimension stable anode

electrolytic copper foil

CAS No.

Category: Iridium-tantalum dimension stable anode

parameters | value |

|---|---|

The earliest copper foil electrodes used lead-based alloy anodes and stainless steel electrodes, but they were gradually replaced by coated titanium anodes due to their defects. Coated titanium electrode has the advantages of light weight, long service life, high current power supply, stable operation, no environmental pollution, etc., and has been widely used in the world. Metal is extracted in sulfuric acid solution by electrolysis and oxygen is extracted from the anode. It is a very important problem to select the appropriate anode material. Titanium electrode coated with tantalum series has low oxygen overpotential and cannot be corroded by electrolyte. Iridium oxide coatings show excellent electrolytic durability. The initial anode is 1.51V, and after 6000 hours, it is 1.64V. The use of lead-based alloy electrodes in electrolytic production (containing Sb6% ~ 15% or containing Ag1%) will cause the lead anode to dissolve, consuming the anode material and affecting the life of the anode. The lead dissolved in the solution will precipitate on the cathode to increase the lead impurities in the metal, reducing the quality of the product. Ruthenium coating will be seriously damaged under this condition, so it is not suitable for use. The initial anode potential was 1.48V, and 1000 hours later, it rose to 2.0V, and the anode had been passivated. The electrode developed by our company has good electrical conductivity; The oxygen evolution potential is low, and the coating oxide grains are fine (up to nanometer level). Long service life (working life up to 40000KA.h/m2).

Advantages:

1、the polar distance is stable

2、 can improve production capacity

3,、the carrying current is high, the current distribution is uniform

4、no pollution on the copper foil

5、low energy consumption

6、Long working hours